Plough Shear MixerPlough shear mixers are highly suited for mixing dry material like powders and granules as well as liquid material like wetting and pastes of low thickness. These mixers are highly efficient for super fast mixing of powders, granules with or without addition of liquids. We manufacture these products using optimum quality raw materials to assure high durability and robust construction. These products are also checked stringently by quality analysts to ensure that defect free range is supplied to our customers.

|

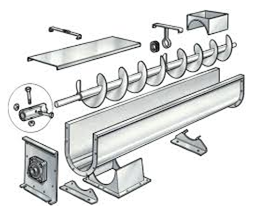

Screw Conveyor

The screw conveyor range offered by us consists of horizontal screw conveyor, horizontal screw feeder and vertical screw conveyor. These conveyor/feeders may feed material from silo/hopper or simply convey it using an upstream feeding device. These screw conveyors are useful in functioning of oil mill plants. Further, these are also used in feeding of seeds and cakes.

Soap Flaker

It is designed to convert Molten Hot Liquid Soap to Solid & Cold form. Chill Drum is a big rotating drum, in which 8 to13 degree Celsius of chilled water circulates continuously. Molten Hot Liquid Soap comes on the top surface in centre of the Chill Drum from Soap Holding Tank (Feed Tank) through gravity, in the form of Lumps, a small drum which is rotating just in same synchronize speed with bigger drum makes a thin layer of 1 to 2 mm of molten hot liquid soap. When this thin layer sticking with bigger drum during complete round, on the other surface end a hard carboned steel blade is fitted out, which scraps that thin layer of Soap. Now, nature of the Soap after scraping is Cold & Solid. At Last, Main function of the Soap Chill Drum is to convert Molten Hot Liquid Soap to Solid & Hard form continuously.

Sigma MixerThis mixture consists of twin trough each fitted with a rotating agitator and each one of these agitator is a heavy duty ‘z’ shaped blade. The product is introduced from the top of the mixture and same access is used to clean the mixture. While in operation the product is loaded up to 40% to 65% of the mixture capacity. The blade can overlap & rotate at same speed or variable speed. In ‘z’ blade two counter rotating ‘z’ – blades fold and shear the material quiet severely. The close clearance produces a shearing and tearing action that is beneficial to the size reduction of solids. These are seldom used for dry solids, but are used for producing dough & thick viscous paste.

|

Agitator

An agitator is a device or mechanism to put something into motion by shaking or stirring. There are three main types of agitation machines are as follow :

The washing machine agitator, which rotates back and forth;

The magnetic agitator, which contains a magnetic bar which rotates about a magnetic field;

The manual agitation, such as with a stirring rod.

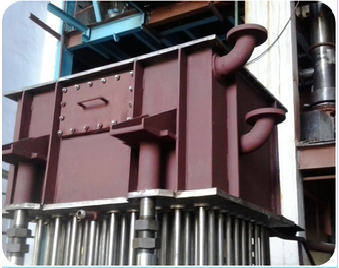

Soap CoolerSoap cooler is an equipment to produce large number of Glycerin soap bars of required shape and size from liquid solution in a short time. The equipment consists of a rectangular tank with top and bottom tube sheets. The tubes are very precisely located and welded to the tube sheets. Center to center of the tubes and parallelism of the tubes is maintained within close tolerances. The elliptical tubes are formed very precisely with close dimensional and shape tolerances. The internal tubes surfaces are finely finished and polished to achieve smooth surface. The mould box is of large capacity and is designed to sustain the internal pressure of circulating water which flows around the tubes for forced cooling. To avoid dead zones more number of inlet sand outlets and baffles are provided.

|

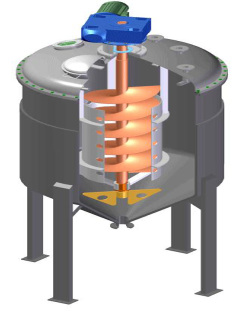

Soap Crutcher

It is robust machine, designed for mixing of raw material to make Soap (i.e. Oils, Caustic, Silicate, Water & other fillers etc.). This is a double jacketed vessel, works with presence of Steam or Thermic fluid Boiler. It is designed of various capacities (2,3,4,5,6 M.T/batch). Inside it a helical thread worm is fitted, which rotates Clockwise & anti Clockwise in the small drum, those is also double jacketed & open from both ends so that thread worm sponifies the raw material up & down very properly. Outer jacketed shell & inner jacketed drum transfer’s heat gently at all point to raw material to final formation of Soap.