Plough Shear Mixer

A wide range of plough shear mixers are highly suited for mixing dry material like powders and granules as well as liquid material like wetting and pastes of low thickness. These mixers are highly efficient for super fast mixing of powders, granules with or without addition of liquids. We manufacture these products using optimum quality raw materials to assure high durability and robust construction. These products are also checked stringently by quality analysts to ensure that defect free range is supplied to our customers.

Paddle Mixer

Paddle mixer is used for mixing solids or liquids of various particle size, density and viscosity. These are fabricated using premium quality materials that are tested for its durability and efficiency. They are available in various dimensions according to the requirements of the customers. They are used in various industrial applications for their features like easy to maintain, durability and flexibility.

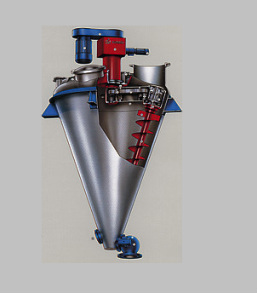

Cone Screw Mixer

Sigma Mixer

High Speed/Shear Mixer

Agitator

An agitator is a device or mechanism to put something into motion by shaking or stirring. There are three main types of agitation machines are as follow :

The washing machine agitator, which rotates back and forth;

The magnetic agitator, which contains a magnetic bar which rotates about a magnetic field;

The manual agitation, such as with a stirring rod.